|

BRHS /

Transport BusesThe market of city buses is highly prioritized for the following reasons:

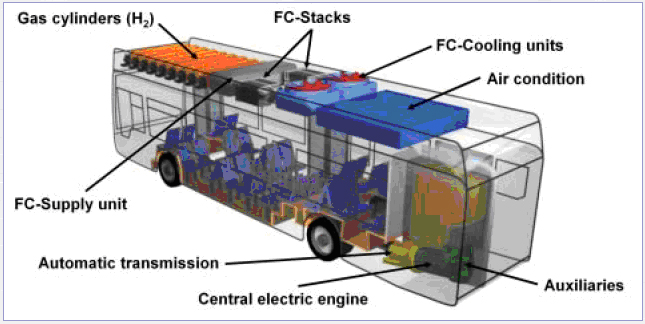

These arguments foster the use of hydrogen and specifically fuel cell operated city buses even though improvement potentials for high efficiency conventional diesel-engines are within reach. A number of prototype ICE and FC powered buses have been built and demonstrated in field tests throughout Europe. In the large European demonstration project, CUTE, 30 hydrogen operated fuel cell buses are test-driven in 9 European cities. A technical drawing showing CUTE fuel cell Citaro buses are shown in figure 2.  Figure 2: Technical drawing from the Merzedes Benz Citaro fuel cell buses used in the CUTE project.[CUTE Project] To store hydrogen on board the CUTE buses, new generation hydrogen storage vessels are used operating at a pressure of 350 bar. Experiences collected with high pressure storage modules by Evobus during the design of natural gas buses contributed to the structural layout of the hydrogen bus. The storage module consists of 9 cylinders each containing 205 litres of geometrical volume. The carbon fibre-wrapped aluminium-lined (Type 3) tanks can contain a total of 44 kg of hydrogen at a nominal pressure of 350 bar. The quantity of hydrogen fuel that can be stored in the cylinders at one time is deemed sufficient for the typical daily range requirements of city transit buses. The hydrogen components are located on the roof of the bus. There are considered to be several advantages with this localization;

The fuel cell stack modules transform the chemical energy contained in the hydrogen fuel into electrical energy used to power the bus. The direct current from the fuel cells is regulated by an electrical inverter, which creates the alternating current to power the central traction engine. This engine is designed for a maximum power of 205 kW which is sufficient to give the fuel cell bus a similar driving and acceleration behaviour as a diesel bus. All other components required for the operation of the bus. e.g. 24 volts supply, air condition compressor, air compressor or steering wheel pump are driven by this central engine. The technical maturity for hydrogen buses is judged as medium with field tests in the hundreds in discussion such that in combination with the simple and cost efficient refueling a market entry is possible even before 2010. However, costs remains a significant barrier to deeper market penetration. << Transport cars and light trucks | Content | Transport other >> |